GUIDELINES

To achieve the results you want and to gain the most out of using our Gaskets Direct website, please see our guidelines below. If you have any questions relating to your order or if you would like to speak to an expert please call our manufacturing facility and head offices on 01425 278011 or email deltasales@deltarubber.co.uk

Our online gasket ordering system has built in limitations to avoid incorrect specifications being submitted. In addition we are able to provide a more competitive quotation where order volume is high. In this instance we ask you complete and submit your order for evaluation.

Whilst our online system does not accommodate some gasket designs, we do have a range of techniques at our disposal at our in house production facility, enabling us to manufacture almost any gasket possible. In this eventuality please contact us with your requirements and we will supply you with a quotation.

PURCHASE ONLINE OR ENQUIRY

Purchase Online or Enquiry Only

Please note some gasket types require evaluation before production can begin due to gasket shape complexity. Please see below which gasket types can be bought online and which can be submitted for quotation and evaluation only:

- Circular/Flange Gasket with Holes - buy online OR submit for quote/evaluation

- Circular Gasket/Washer - buy online OR submit for quote/evaluation

- Square Rectangular Gasket with Holes - submit for quote/evaluation only

- Square Rectangular Gasket - buy online OR submit for quote/evaluation

- Solid Disc - buy online OR submit for quote/evaluation

- Solid Square - buy online OR submit for quote/evaluation

- Custom / Specialist Gasket - submit for quote/evaluation only

USER GUIDE

User Guide

Our online ordering system has been developed for our CNC Digital Cutting Machine. Due to the mechanical techniques used to cut the smallest and largest of gaskets, we have factored in order thresholds based on material thickness and your specifications. These thresholds take into account the following rules where applicable.

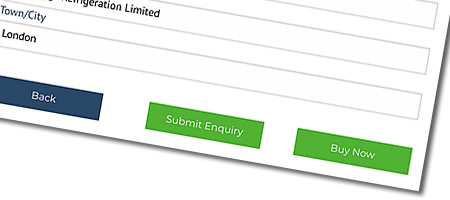

ID - INSIDE DIAMETER

Your inside diameter of your gasket may be no smaller than your chosen gasket material thickness. This threshold avoids material tears or imperfections upon production.

Example: If you have chosen Viton rubber at 3.00mm thick, the minimum ID you may have is 3mm.

See diagram [1] - Measurement [A] must be equal to or greater than measurement [B]

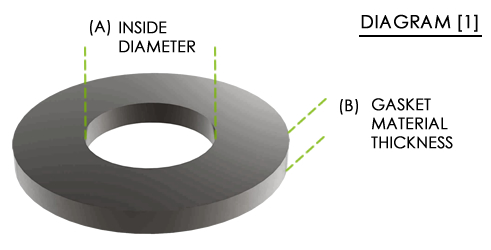

OD - OUTSIDE DIAMETER

Your Outside Diameter is limited to 1000mm on this online ordering system.

We can produce much larger gaskets to your specifications using a range of production techniques, please select "Custom/Specialist Gasket" from step 1 and fill out the form submitting any accompanying notes and images.

We will respond to your gasket quotation request within one hour Monday to Friday, 9.00am to 5.00pm.

See diagram [2] - Measurement [A] Outside Diameter

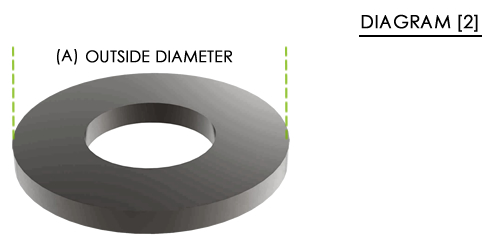

FLANGE SIZE

Your gasket flange width must not be smaller than your gasket material thickness (see diagram). Flange size is the difference between your OD (Oustide Diameter) and ID (Inside Diameter) at its smallest point.

Example: If you have chosen Viton rubber at 5.00mm thick and have an ID of 5.00mm, your OD must be at least 15.00mm (material thickness plus ID).

See diagram [3] - Measurement [A] must not be smaller than Measurement [B]

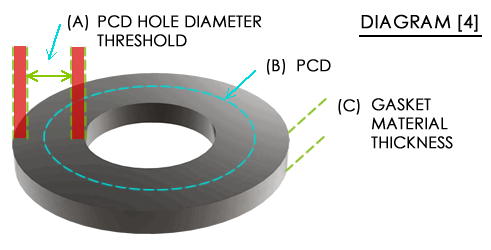

PCD (PITCH CIRCLE DIAMETER)

The PCD must not exceed the OD (Outside Diameter) or be smaller than your ID (Inside Diameter) of your gasket AND leave enough rubber either side of your PCD hole to a thickness of or greater than your material thickness selection (see diagram).

To ensure cutting your gasket is viable, ensure your flange size (Outside Diameter minus Inside Diameter) is equal to a minimum of your PCD hole size diameter plus 2x your material thickness choice.

Example: If you have chosen Viton rubber at 6.00mm thick, PCD holes at 4.00 diameter and have an ID of 6.00mm, your PCD should be marked at 22mm and your OD should be 38mm (minimum feasable production threshold), giving a flange width of 16mm.

See diagram [4] - Measurement [A] must allow space for your material thickness [C] either side of your PCD hole diameter once your PCD has been taken into account.

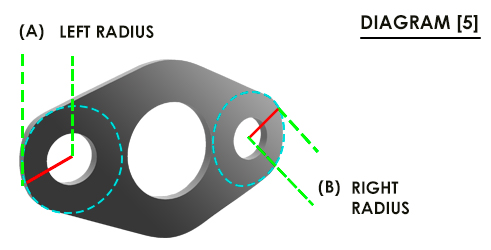

RLR (RIGHT / LEFT RADIUS)

The RLR is the specific measurement for the right radius and left radius of your oilpipe gasket.

See diagram [5] - Showing measurements required highlighted by the red line within the diagram.

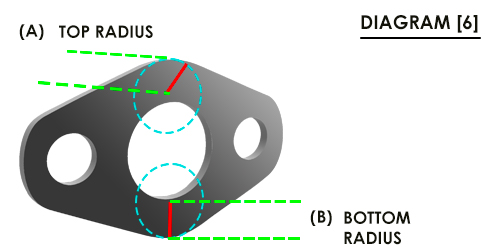

TBR (TOP / BOTTOM RADIUS)

The TBR is is the specific measurement for the top edge radius and bottom edge radius of your oilpipe gasket. The TBR is taken from the center of the invisible cirle that gives the top edge and bottom edge curve for your oil pipe gasket.

See diagram [6] - Showing measurements required highlighted by the red line within the diagram.

ORDERS OVER £500.00

To ensure we give you the most competitive quotation we have limited our quote/online ordering system to £500.00. Typically we can reduce production costings and therefore our customer quotations above this value. If your quote/order value exceeds this, please submit for evaluation and a dedicated member of the team will respond to your enquiry as soon as possible.UK MAINLAND DELIVERY ONLY

We currently only ship to mainland UK addresses. For orders in the Highlands and Islands, or International orders, please Submit Enquiry only and we will respond promptly with your quotation and up to date courier costings. Please see our delivery page for more details.

IF YOU ARE UNSURE CONTACT US

Contact us if you are unsure

If you are uncertain about your gasket submission please select "Submit Enquiry". We cannot refund your incorrect order once production has begun.